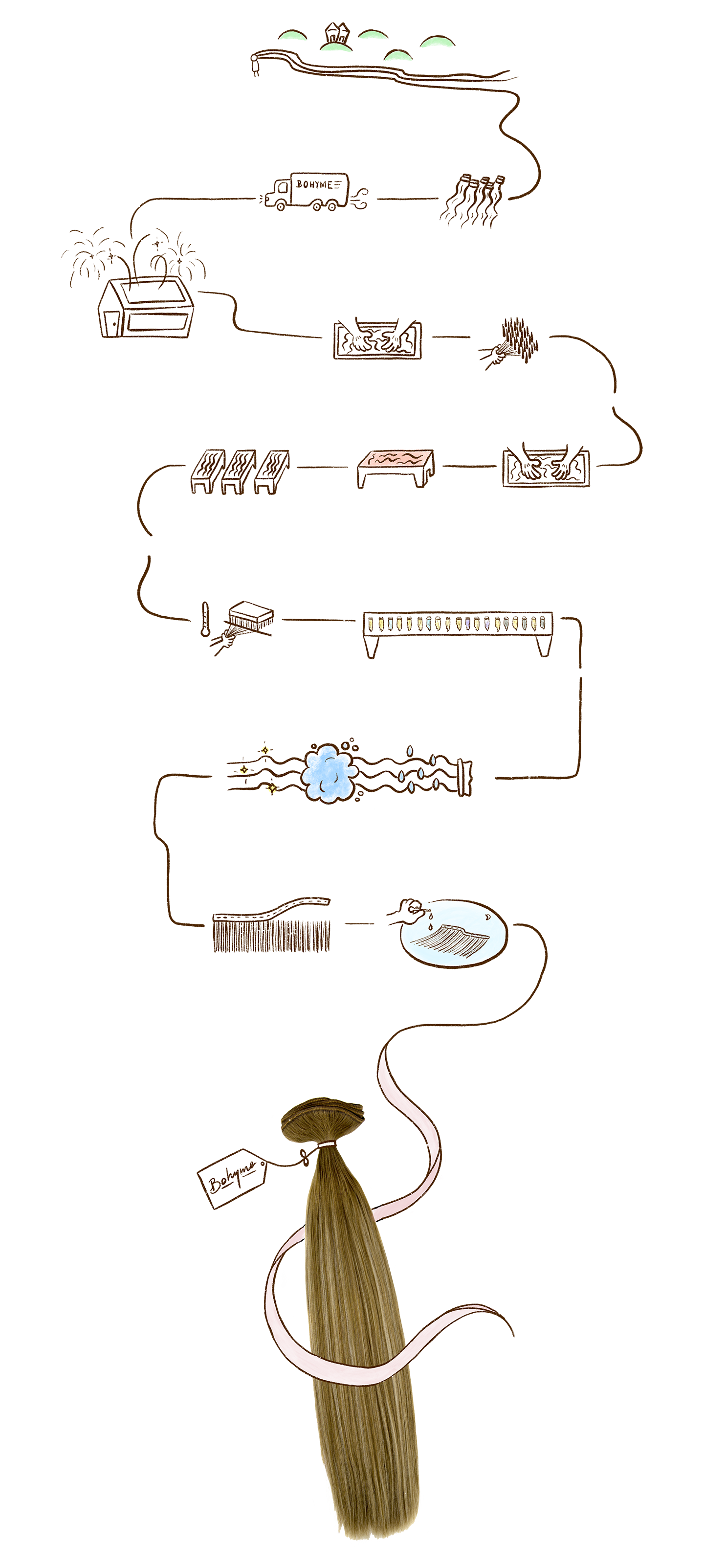

Every story has a beginning…

The Magic Behind The Hair

We value transparency and the willingness to share information regarding our hair extension production from beginning to end. Bohyme has been around since 1978 and have a vast amount of experience in the hair industry. Our longevity allows us to be a pioneer in the hair extension industry and we are proud of leading the way in terms of improving and making positive changes.

Behind every great product, is a great story of how it comes to be. From sourcing to distribution, Bohyme® takes part in every step of the entire process. This is why they can assure you that every hair strand they use:

- Meets strict standards

- Is ethically sourced solely from healthy human Remi® hair

- Contains no toxic chemicals for you and the environment

respect human rights

We will never work with anyone who is willing to sacrifice the quality of human life for a larger profit.

Across the company, we implement standards and policies to protect the human rights of our employees and partners. It is how we are able to build long-lasting relationships with customers, partners and communities around the world. We believe that respecting international human rights laws and standards is fundamental to our work as a responsible company.

We believe in fair trade practices honoring fair wages and clean working environments in our own manufacturing facilities, in our partner factories, in our distributor practices and in our offices and warehouse.

Our respect for human rights extends to all of the individuals who take part in the hair creation process in both China and Korea. We make sure everyone is treated fairly and workspaces are clean and well ventilated.

Through dialogues with local and global human rights experts we have deepened our understanding of human rights abuses and poor labor practices and identified areas in our company where related risks are likely to be high.

The first and most important aspect of respecting human rights in the hair extensions industry is the treatment of hair donors and manufacturing facility employees. Respect, safe, clean working conditions and fair wages are essential.

facts from Bohyme® factories

To make sure that all working conditions and human rights are being respected in all facilities, we work with third-party auditors to evaluate factors like fair wages, labor conditions, reasonable hours and a safe work environment. Inspections are performed twice a year.

In 2012, our factory received the Work Safety Standardization Certificate and a Quality Management System Certificate.

In 2018, investments were made in improved ventilation equipment, providing healthier air circulation.

ENVIRONMENT

Continuously educating ourselves to the harmful side effects caused by the hair industry, we believe we must take measurable actions to protect the environment and encourage others to join us in our commitment to sustainability. Across all areas of our business, we are promoting initiatives that reduce the environmental impact of our activities.

Across all areas of our business, we are promoting initiatives that reduce the environmental impact of our activities.

| Minimizing water waste | We installed special water treatment in our factory to recycle wastewater. |

| No synthetic hair | Bohyme® hair is created only with 100% human hair. |

| No toxic by products | We use only mild, organic fruit shampoos to wash the hair and high-grade food dyes to color the hair. Wave patterns are created without chemicals. |

| No paper policy | We implemented a no paper policy for internal operations. We only print catalogs, brochures and other marketing mate- rials by special request. |

| Eliminating packaging sections and turning to recyclable packaging | We are reducing our packaging and our newest collection, Ethos®, was created with fully recyclable packaging. |

| Reusing and recycling shipping boxes | In our warehouse, we reuse, donate and recycle shipping boxes in creative ways to reduce waste. |

| Recycling waste | We employ a strong strategy to reduce waste from every facet of our company. |

| Protecting animals | We have never tested our products or ingredients on animals. |

responsible manufacturing

We ensure that working conditions are safe for both the product and the employees by monitoring the intricate processes involved with hair extensions. Our factory has formal EIA (Environmental Impact Assessment) approval, is a proud member of the Environmental Protection Association, and holds Safety Standardization Certificates from credible agencies overseas.

We refuse to use any synthetically derived ingredients, which create toxic by-products during manufacturing. This way we can be positive that our products don’t impose negative impacts on the environment or those involved in the creation process.

no chemicals used

Bohyme® utilizes traditional techniques and methods to reduce the amount of pollutants that more modern machines release. This also allows for our handcrafted items to maintain the high quality necessary for consistency and longevity.

Bohyme® is known for a large variety of textures and colors. Unfortunately, many products on the market use harsh chemicals,like dyes and bleaches, to produce their colors and styles. These chemicals then enter the environment through non-recycled,unfiltered water. After much research, Bohyme® was able to develop processes that allow us to create even more colors and textures without harming the natural world, while at the same time resulting in high-quality, long-lasting products.

How do we do create Bohyme® hair without chemicals?

| WAVE PATTERNS | COLORS |

| No chemicals are used to create our wave patterns. We use a heat rod and steam technique. The pattern loosens over time through wear and wash. | All of our shades are made using high-grade food dyes and a gentle bath. Hair soaks for 21 to 40 days to ensure the cuticles stay intact. This process minimizes hair damage. Many other companies bleach and color in just a few days, which doesn’t preserve the health of the hair. |

preventing wastewater pollution

At Bohyme®, we aim to ensure the sustainable use of water by preserving water circulation in our systems.

Our production sites have been working to reduce water consumption since they were established. In order to make more effective use of water, we’ve made capital investments, particularly in water circulation equipment.

We have all heard about the $532 billion that the beauty industry wastes on water, while water shortages are expected to seriously impact two billion people by 2025. Through research and multiple educational sources, we found that the entire hair extensions industry’s use of traditional hair cleaning and processing methods throws out and wastes millions of gallons of water each year. With the hair extensions and wig industry growing fast and without implementing important changes, these numbers will be much worse. If this water usage trend continues, water poverty is set to impact two-thirds of the population by 2025.

To combat this wastewater issue, we worked together with an environmental tech company overseas and invested our capital to install special water treatment equipment in our factory. This equipment allows us to recycle wastewater and use it up to 10 more times before it’s disposed. Our factory has formal EIA (Environmental Impact Assessment) approval and invests resources annually to come up with innovative ways to treat and eliminate pollution caused by wastewater.

water recycling stages

| 1. Removing oil and large particles | The first step of recycling wastewater is to remove any oil and large particles from the water. This first step is possible thanks to the combined efforts of the triple interceptor and oil separator. A triple interceptor is a three-compartment tank where water flows from the first compartment to the second, and then from the second to the third. The main purpose of a triple interceptor is to allow time for any particles to sink to the bottom of the first compartment. Once wastewater has gone through a triple interceptor, it enters the oil and water separator. Since oil is less dense than water it will float to the top of the tank, where it can be collected and removed. |

| 2. Filtration | After oil and large particles have been removed, the wastewater is placed into a process tank where it is stored before being pumped into a filtration system tank. The first stage consists of the filtration system. Water is pushed with high pressure through sand and other granular particles to remove any large particles still present in the water. To ensure that the required maximum particle size is achieved, water is then put through a three-stage cartridge filtration, capable of reducing sediment size to 1 micron. |

| 3. Removing chemicals | The next step in the water recycling system depends on the presence, type, and amount of surfactants in the water. Surfactants are commonly found in hair detergents and dyes. Manufacturers have created fast-breaking detergents, which lower the water surface tension, allowing water and soil to emulsify. After some time has passed, the surface tension returns to normal allowing the separation of water and soil. Our system treats this water in a tank using bacteria to decompose the detergent. |

| 4. Sterilization | Once the water is free of detergents, the sterilization phase begins. Wastewater is full of disease-causing organisms, viruses, parasites, and bacteria that are found in poor-quality water. Our system utilizes UV sterilization by running water under UV light rays. After this, the water is ready to be reused to clean and treat the next batch of hair. |

reducing waste

Bohyme® employs a strong strategy toreduce waste from every facet of our company. We continue to implement important strategic initiatives that reduce our environmental footprintto optimize our resource use and minimize waste.

Forests are vital to our planet. They provide clean air and water, reduce climate change, and support those who depend on forest ecosystems for food, fresh water, clothing, medicine and shelter. Unfortunately, with every passing minute, forests are being destroyed, leading to the loss of millions of acres annually. It is Bohyme’s duty to think of as many ways as possible to reduce waste. We started with our paper use and product packaging.

PACKAGING

Since 2014, we’ve worked on reducing the size, weight, and production waste from packaging. We continuously challenge our packaging partners to offer packaging that can be recycled whenever possible.

All parts of the packaging for our newest collection, Ethos®, are created with fully recyclable materials, even plastic bags.

PRINTING

Instead of printing catalogs and brochures, we’ve created downloadable resources. All information about our products is available on our websites and we’ll supply printed versions by special request.

Bohyme® implemented a no paper policy for internal operations. We utilize digital forms, invoices, and fulfillment documents. With this positive step, we’ve reduced 85% of all paper use.

SHIPPING

In our warehouse, we reuse, donate and recycle shipping boxes creatively to reduce waste.

All pick-up orders are packed in recyclable paper bags. We don’t use any fillers in shipments and our fulfillment team cuts each package to size. This leads to less waste and lower shipping rates for our clients!